When unexpected pressure loss occurs in pneumatic conveying systems, it results in not enough airflow to transport your materials effectively. Instead, they accumulate at the bottom of your pipes, creating blockages that require extensive downtime and unnecessary maintenance costs to fix. Pressure loss can also drive up operating costs, as your system will require greater air volume and velocity to function as normal, increasing power consumption.

Most manufacturers look for air leaks, high air moisture, insufficient airflow, or flaws in their pipeline feeder to explain unexpected pressure loss. But it can actually be caused by the design or condition of the system itself. In fact, one culprit of chronic pressure loss that you might not suspect is the centerline radius (CLR) of your pneumatic conveying elbows.

Pressure loss in pneumatic conveying elbows

A major cause of pressure loss within a pneumatic conveying system is friction between your dry bulk materials and the inside of your pipe walls.

New pipes typically have a smooth surface. This allows your materials to glide through your pipes with as little friction as possible.

But over time, your materials wear away at the inside of your pipes. This creates irregular surfaces, which increase friction and therefore pressure loss.

When it comes to friction and pressure loss within pneumatic conveying elbows, two of the biggest factors are length and CLR.

All elbows create a pressure loss no matter the CLR or length. What you want to do is mitigate that loss to what is acceptable for your system. The longer the CLR the greater the loss, the shorter the CLR the lesser the loss. However, abrupt changes in direction cause an even more significant loss in pressure, so ultra-short radius fittings like dead-end tees, mitered elbows, or vortex elbows create more loss than longer CLR elbows. Summarily you want to use the shortest CLR that makes sense for the kind of product being conveyed.

How do centerline radius and pressure loss affect system design?

The relationship between elbow dimensions and pressure loss presents a difficult balancing act for pneumatic conveying system designers.

On the one hand, short or shallow-angled elbows typically create less pressure loss. But overusing these can require you to extend the total length of your pipework so your materials can reach their destination. This creates more opportunities for friction and pressure loss elsewhere in your system.

On the other hand, long or sharp-angle elbows tend to increase pressure loss through greater friction. But they can also direct your materials to their destination much more quickly and shorten total pipe length.

The design of your pneumatic conveying system depends on several factors, including available space, materials characteristics, and target throughput. In many cases, these – rather than ideal system design – will dictate the types of elbows you install.

How to calculate centerline radius

The CLR of a pneumatic conveying elbow is the distance from the center of the elbow’s curve to the centerline (axis) of the pipe. This value is expressed as a number multiplied by the pipe or tube size.

To calculate CLR, first find where the ‘degrees of bend’ lines on the elbow intersect. The distance between this point and the center of your elbow is your CLR. This measurement can be taken from any point along the elbow.

How to calculate pressure drop in circular pipe elbows

Pressure drop refers to the difference in pressure between two points in a pneumatic conveying system. Calculating pressure drop can be useful for calibrating a system efficiently, but can also be used to identify unexpected pressure loss.

Unfortunately, figuring out the actual pressure drop in a pneumatic conveying elbow is phenomenally difficult. Not only is there a pressure gradient across your entire system, but you must also account for regular friction of gas and solids as well as re-acceleration after the bend. For almost all operators and plant managers, trial and error is the easiest and most reliable way to design out pressure loss in pipe elbows.

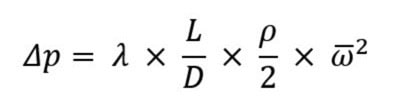

However, if you wish to calculate a rough estimate of pressure drop in circular pipe elbows, it’s easiest to treat the elbow as equivalent to a length of straight pipe. Then, you can use the following equation:

- ΔP = Pressure drop (Pa or Kg/ms2)

- λ = Pipe friction coefficient

- L = Length of pipe (m)

- D = Pipe diameter (m)

- ρ = Density of fluid (Kg/m3)

- ω = Flow velocity (m/s)

5 ways to minimize pressure loss in pneumatic conveying elbows

1)Use elbows with a smooth internal finish: Elbows that have an irregular surface create additional friction, leading to greater pressure loss. Be sure to use elbows with a smooth, durable internal finish, and replace them when wear takes its toll.

2)Increase pipe diameter: The larger the diameter of your elbows, the easier your materials will flow through them. This helps to reduce friction and wear, and by extension pressure loss.

3)Reduce bends: The best way to minimize pressure loss in pneumatic conveying elbows is simply to remove elbows wherever possible. Reevaluate your system design to see where you might be able to streamline your pipework.

4)Minimize height: If your pneumatic conveying system is much taller than necessary, it likely includes too many elbows, or elbows that are too large. This will also shorten overall pipe length, further reducing pressure loss.

5)Use standard radius elbows: With their shorter length, standard-radius elbows are much better at preventing pressure loss than long-radius elbows. But remember to keep efficient system design in mind. Shorter radius elbows can cause pipe abrasion or product friability issues.

Reduce pressure loss with durable, high-quality elbows

The best way to avoid unexpected pressure loss caused by pneumatic conveying elbows is to streamline your system design wherever possible. However, even if you can remove one or two elbows, these components are still vital for conveying your dry bulk materials effectively. That means those that remain should be of the highest possible quality.

With over 40 years in the industry, the expert team at Progressive Products Inc. has designed and manufactured the very best pneumatic conveying elbows. From hollow-back and cement-back elbows to our patented Ceram-Back® elbow, each one is specially designed to prevent system wear, product degradation, and system pressure loss. And if you can’t find the precise elbow you want, we can custom manufacture new components to your specifications.

Browse our selection of elbows and other fittings now, then get in touch for your quick quote.