Pneumatic conveying systems are often used for industrial and commercial purposes, moving bulk goods such as powders, pellets, granules, and other fluidizable materials from one place to another without using mechanical conveyors. Instead, these systems use a vacuum or pressure system to transport material through an enclosed, airtight pipeline.

To understand how these systems work, we will first examine how the two types of pneumatic conveying systems — vacuum and pressure — function and how they differ from one another. We’ll also look at how the material being transported changes the design of a pneumatic system and how these systems work.

Vacuum vs. Pressure Systems

Pneumatic conveying systems can be classified into one of two broad types: vacuum conveying systems and pressure conveying systems.

Vacuum conveying systems use a vacuum pump to suck the air out of the pipeline to pull materials through the system. These systems are ideal for dilute phase conveying, allowing light and moist materials to be transported through the system.

In contrast, pressure conveying systems use a positive air pressure system created by a blower or compressor to push materials through the pipeline. Material is added to the line via a rotary airlock, allowing it to enter the airstream without affecting system pressure.

Dilute and Dense Phase Conveying

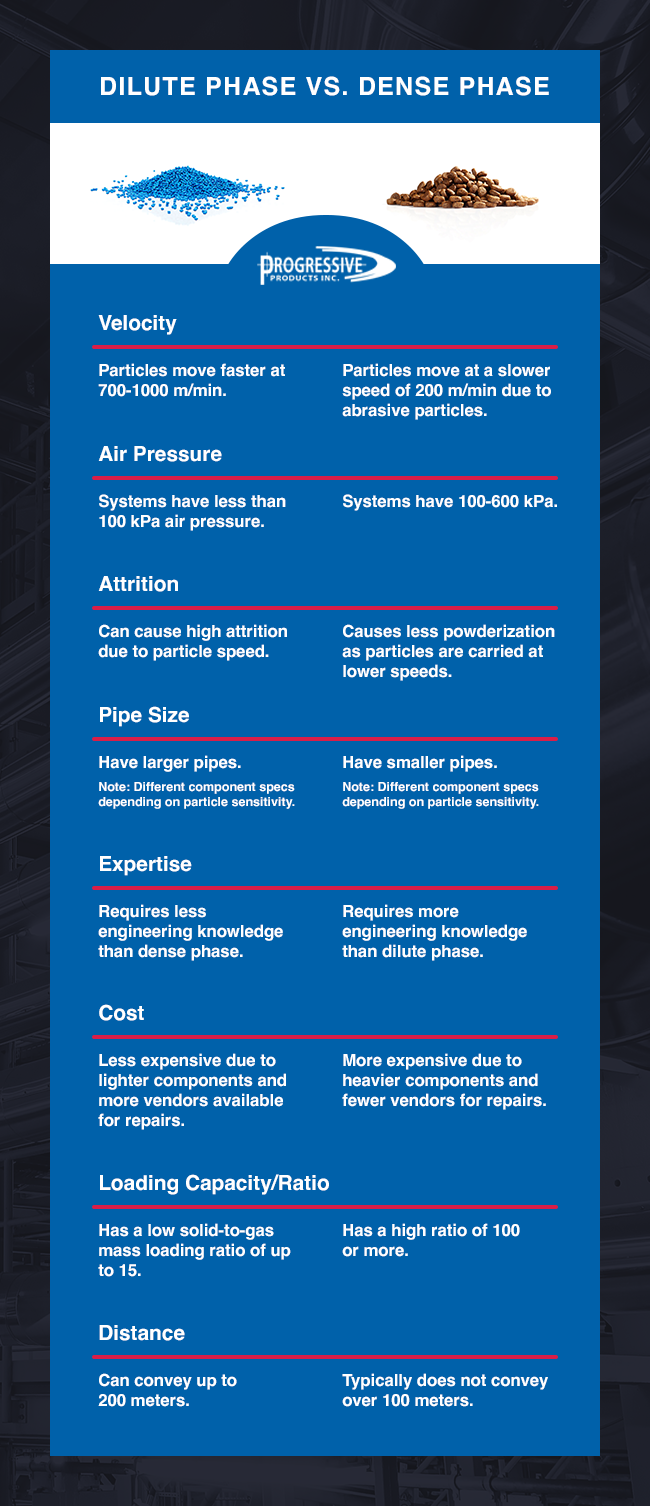

Another critical aspect of understanding how pneumatic conveyors function is knowing whether they are designed with dilute phase or dense phase conveying in mind.

Dilute phase conveying is when a material is completely suspended in air within the pipeline. In this system, the material is diluted with air and very fluid, allowing it to easily transfer from both multiple inputs and outputs to various locations along a pipe if needed. This method is defined by low pressure in the pipeline and high velocity of the material.

Dense phase conveying is when a material is too heavy to be suspended and instead creates a type of slur that forms on the bottom of a pipeline. As the dense material builds up, the pressure in the system also builds until it is eventually able to push the material forward through the line. This method is defined by high pressure in the pipeline and low velocity of the material.

Keep in mind that while dilute phase can be either vacuum or pressure, dense phase is always pressure.

How Material Moves Through the System

Now that we know that pneumatic systems use either a pressure or vacuum system to move either dilute or dense phase materials, let's examine how each one of these systems works.

Vacuum Pneumatic Conveyor

A vacuum pneumatic conveyor will use compressors, blowers, or fans to move air through its pipeline. By creating a difference in pressure between the beginning and endpoint of the pipeline system, it creates a vacuum that pulls the material through the line.

The material is kept in an overhead storage bin known as a feeder that uses gravity to introduce the material into the line, though mechanical feeders can also be used. In order to avoid a loss of pressure, a rotary airlock is located between the feeder and the line to allow the material to be continually fed into the line without affecting the line’s pressure.

From there, the material will be in a dilute phase and travel throughout the line until it reaches a receiving bin, where it will be stored until it is needed.

Pressure Pneumatic Conveyor

For pressure pneumatic conveyors, the material is entered into a pressurized line, where high pressures force the material into and through the conveyor. Special air injectors can introduce more air into various points in the system to help fluidize the material and move it to a waiting storage bin.

As you can see, there are many factors that lead to how a pneumatic conveying system works. The material being transported will determine if a vacuum or pressure system is used, which will determine if it moves as a dilute or dense phase substance.

At Progressive Products Inc., we have a wide range of components for your pneumatic conveying system. You can view our entire range of products or contact us so that we can see what pneumatic conveying solutions are right for you.