A flat back elbow is designed to resist the abrasion and impact caused by large particles traveling through a pneumatic conveying system. Its name comes from the fact that the back, or outer curve of the elbow, is flat due to the supporting metal plate. Internally, most flat back elbow designs have a ceramic lining that further protects this crucial component from abrasion.

What Is A Flat Back Elbow?

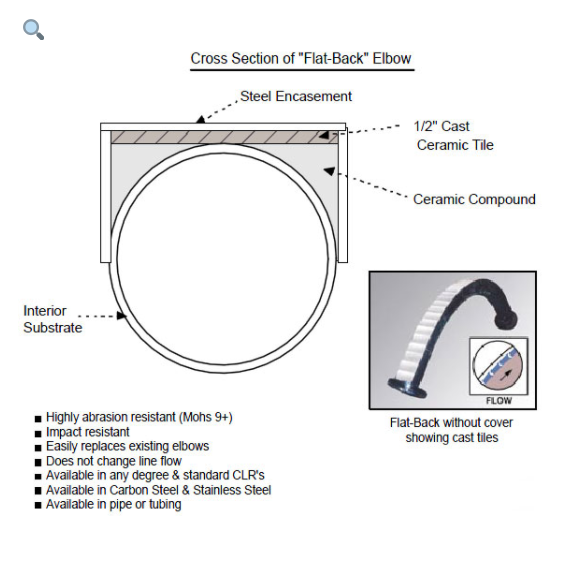

A flat back elbow is a type of bend for a pneumatic conveying system that has a steel encasement. This encasement is a flat, metal support along the back or outer curve of the elbow, which dramatically improves the component’s life by taking the brunt of abrasive forces. The steel encasement, also known as a box back, is reinforced with ceramic tiles, as well as filled with ceramic compounds, like ceramic epoxy, in order to further extend the elbow’s life.

This graphic shows a cross-section of a flat back elbow:

When the particles of a bulk material, such as plastic pellets or grain, are conveyed through a pneumatic system, they exert impact forces that cause friction on the inner walls of the pipes and tubes they’re traveling through. Impact forces are particularly strong at junctions where the bulk solid particles change direction. This is because the centripetal and centrifugal forces cause the momentum of particles to increase, and this results in significant damage to components.

All of this means that elbows joining pipes and tubes together are subjected to a constant flow of destructive forces that can eventually cause wear and tear to the elbows; and if the elbows aren’t protected, they’ll eventually break down. This could have a range of negative knock-on effects for a business, from extended periods of downtime to expensive repairs, so investing in a flat back elbow that’s designed to withstand abrasion is particularly recommended if you’re conveying highly abrasive products.

How Does A Flat Back Elbow Work?

Flat back elbows work by transferring the surface damage caused by abrasive particles to the outer steel encasement, thus protecting the elbow inside.

Because flat back elbows are lined with ceramic, they’re often used in heavy industry as they’re designed to be tough and resistant to particle abrasions. The extra metal plate support, the ceramic compound, and the ceramic tiles all work together to not only protect the elbow from wear, but also from bending. This minimizes the amount of damage caused and, in turn, improves the life expectancy of the elbow. Flat back elbows, similar to our Ceram-back® elbows, feature a reinforced back where most of the wear is seen.

When Would You Use A Flat Back Elbow?

Flat back elbows are very useful in industries that convey bulk solid particles that are large and abrasive, such as the grain industry as well as those industries conveying aggregates. In these environments, flat back elbows are capable of handling the strong impacts and high temperatures that often come along with conveying dry bulk materials.

There are few ways in which flat back elbows can improve how your pneumatic conveying system operates:

- They’re ideal for installing in hard-to-reach areas since the need to replace in these areas is decreased

- They’re versatile and can be easily integrated with different types of pipe ends

- There’s no need to apply special coatings in order to make the elbows heat-resistant

- They’re very versatile as they can be used in systems of all different sizes. Their toughness makes them capable of handling large volumes of materials, but they can also be used in much narrower systems, too

If any of these are ticking your boxes, it might be time to switch over to using flat back elbows in your pneumatic conveying system. You’ll find that making this decision will not only improve the longevity of your components, it will also improve the overall efficiency of your system, leading to better productivity and reduced expenses.

What Are The Pros And Cons Of Using A Flat Back Elbow?

Just like other types of elbows used in pneumatic conveying systems, flat back elbows come with their own set of pros and cons, depending on how you use them:

Pros of using flat back elbows:

- Tough and resistant to abrasion

- Tolerant of higher temperatures

- Can withstand impact, even at high speeds

- Can be fabricated using various sizes of pipe or tube, and nearly any centerline required

Cons of using flat back elbows:

- Can be costly to buy up front (although their longevity can make them very cost-effective over time)

- They can be quite heavy and bulky

- They’re not needed for every industry, depending on what you’re conveying

- Flat back elbows are directional

What Are The Differences Between Ceramic Compound And Ceramic Tile?

Flat back elbows include both ceramic compound and ceramic tile, but what are the differences? It all comes down to what they’re composed of: while the tiles are made from cast ceramic materials, the ceramic compound comes in the form of epoxy.

There’s also a difference in how ceramic compounds and tiles function inside flat back elbows. Ceramic tiles line the interior surface of the steel encasement. Meanwhile, ceramic compounds fill the space between the steel encasement and the elbow tube. With that in mind, ceramic tile is meant to take the brunt of abrasion, thus preventing the elbow from bending. Once a tile wears through, you may have a few weeks before the back will develop a hole. Ceramic compound, on the other hand, is meant to offer protection in the lower wear parts of the elbow.

When Would You Use Ceramic Compound vs Ceramic Tile?

You can use both ceramic compound and ceramic tile in a flat back elbow as they each provide different forms of protection. However, it all comes down to the needs of your pneumatic conveying system and what it is you’re trying to achieve.

If you want a simple, first-line defence against wear and tear, ceramic compound is a harder surface to wear through than a bare metal elbow. If you have heat concerns, large particle size or are conveying a very abrasive product, ceramic tiles might be a better bet because of the structural integrity they bring to a component.

If you’re unsure about which type of elbow would best optimize your pneumatic conveying system, contact our team of experts.