Smooth flow within a pneumatic conveying system is vital for maintaining high productivity. If the speed at which your materials travel through your system is too low, they can build up within the pipes and create blockages.

When this occurs, you’ll need to shut down your system right away to clear those blockages out, costing you time and money. Otherwise, the increasing pressure could lead to leaks or system failure. And if you convey grain or other small foodstuffs, trapped product can result in mold or rot, contaminating your entire batch.

Finding the correct saltation velocity (USALT) and choking velocity (UCH) for your system allows you to avoid blockages by ensuring a consistent flow of dry bulk materials. But even though these two values perform a similar function, USALT is always higher than UCH. That’s because of the different challenges in maintaining solids in horizontal and vertical pipes.

What is saltation velocity?

Dry bulk materials are typically transported in a dilute-phase pneumatic conveying system. This is a high-velocity system in which materials are suspended in the air as they travel through the pipes.

The idea is that since the materials don’t settle along the bottom of the pipes, they don’t accumulate or lead to blockages. But this is only true if the velocity at which they’re traveling is high enough to keep them airborne.

USALT is the minimum gas or air-conveying velocity required to keep particles suspended within horizontal pipes. When the system’s velocity drops below USALT, materials begin to deposit at the bottom of the pipes, which can lead to blockages. To avoid this, the minimum velocity at which materials move through horizontal pipes – known as pick-up speed – is typically set at least 20% higher than USALT.

How to calculate saltation velocity

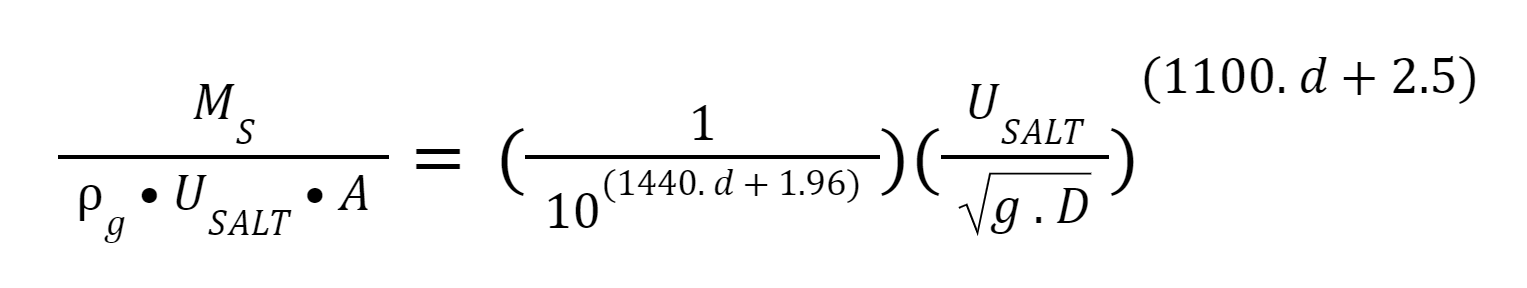

The USALT required by your dilute-phase pneumatic conveying system depends on your plant design and the dry bulk materials you convey. To work out your system’s USALT and calibrate the correct pick-up speed, start by using the Rizk calculation formula:

MSgUSALT A=(110(1440. d + 1.96))(USALTg . D)(1100. d + 2.5)

With:

Ms = Solids mass flow rate (kg/s)

ρg = Gas density (kg/m3)

USALT = Saltation velocity (m/s)

d = Particle diameter (m)

D = Pipe diameter (m)

g in S.I. units

The Rizk formula is a great jumping off point for determining your system’s USALT. But with an average deviation of +/- 54%, it can be very imprecise. So be sure to perform a professional assessment of the resulting value and adjust your pick-up speed as necessary.

What is choking velocity?

UCH is fundamentally the same as USALT in that it’s the minimum velocity required to keep particles from accumulating at the bottom of pneumatic conveying pipes. But while USALT is related to horizontal pipes, the UCH value is for vertical pipes. UCH is always lower than USALT, which in turn is always lower than pick-up speed.

How to calculate choking velocity

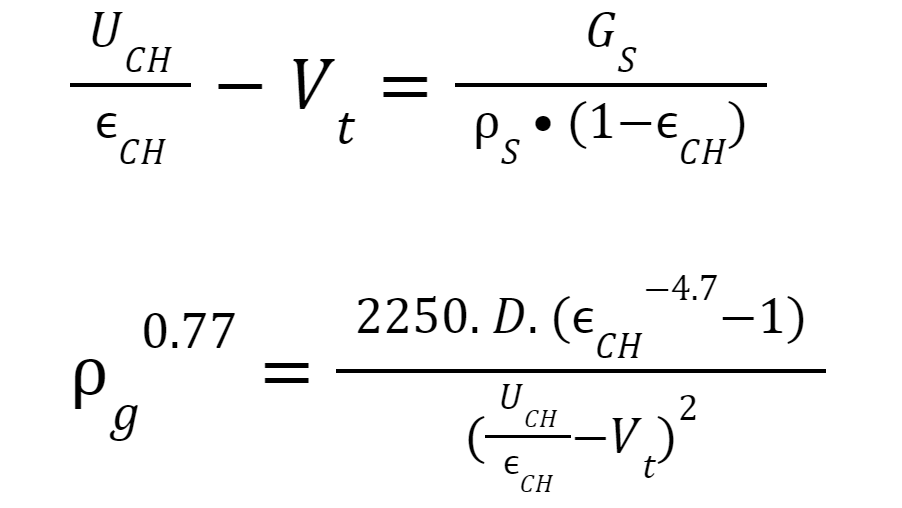

You can calculate UCH using the following equations devised by Punwani et al. as outlined in Principles of Powder Technology (1990):

With:

Gs = Mass flux of Solids (kg/m2/s)

ϵCH = the voidage of the pipe at the choking velocity UCH = (1 - volumetric concentration of solids)

ρs = Particle density (kg/m3)

ρg = Gas density (kg/m3)

UCH = Choking velocity (m/s)

D = Pipe diameter (m)

All in S.I. units

To accurately calculate UCH, you must solve both equations simultaneously through trial and error.

Why does saltation velocity always exceed choking velocity?

Although the equations for calculating these two values are fairly complex, the reason why USALT is higher than UCH is surprisingly simple: in a dilute-phase pneumatic conveying system, it’s harder to keep dry bulk materials airborne in horizontal pipes as opposed to vertical pipes. In fact, USALT is often three to six times higher than UCH.

How to decrease saltation velocity requirements

In an effort to raise system velocity while lowering gas or air requirements, some companies try to decrease the diameter of their pipes. But doing so also increases the rate of flow. This in turn increases USALT, meaning there’s no net gain.

That said, there is one method that’s proven to reduce USALT. By angling a horizontal pipe downwards, even by as little as 15 degrees, you can decrease the velocity required to keep materials from accumulating along the bottom of your pipes.

Push your productivity even further with high-performance components

Once you’ve successfully determined your system’s USALT and UCH and found the sweet spot in your pick-up speed, you’re ready to move materials without worrying about blockages. But the science behind pneumatic conveying is only part of reaching your optimal rate of productivity. To further reduce system downtime and lower maintenance costs, you also need durable, cost-effective, abrasion-resistant components.

For more than 40 years, Progressive Products has been manufacturing high-performing elbows, diverters, lump breakers, and airlocks for all manner of dry bulk industries. From grains, plastics, and pet food to mining and water treatment, our parts help companies across the world cut costs and improve operational efficiency. And if we don’t have the components you need, we can custom manufacture them to your precise specifications.

Get in touch with our friendly expert team today to find out how our industry-leading parts can enhance your pneumatic conveying system.